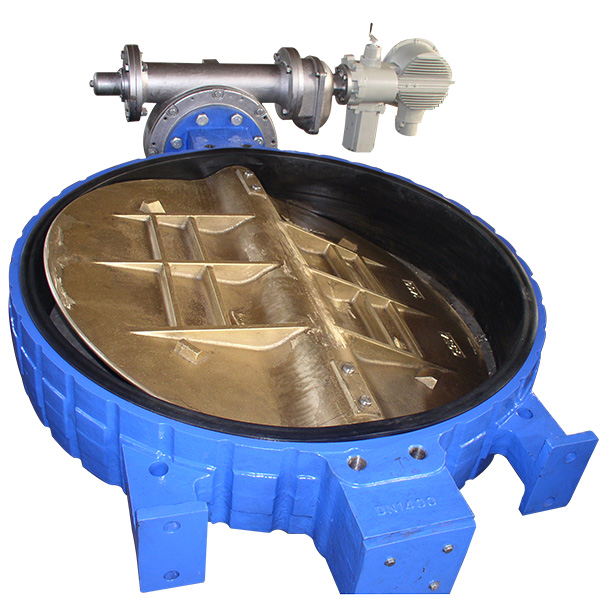

Eccentric Butterfly Valve BFV-1010

Quick Detail

Design standard: API 609.

Body material: DUCTILE IRON ASTM A536

Nominal diameter: DN1400 56″

Pressure: CL150 (PN20)

End connection: Wafer

Face to face: EN558 Series 20

Top flange ISO5211.

Bi-direction Seal, Renewable seat Design

Mode of operation: Lever

Test and inspection: API 598. EN1226

Epoxy Powder Coated inside and outside Min. 250 microns.

Available Body Material: Ductile Iron , Carbon steel, Stainless steel, Alloy steel.

Available Disc Material: Ductile iron, SS304, SS316, Bronze

Optional Seat: EPDM, NBR, PTFE, Teflon. Neoprene

Optional End connection: Wafer, Lug, Flanged.

Optional Body Design: Eccentric or Concentric centerline

Face to face: EN558 Series 13/14, long type or short type

Normal diameter: 2″~56″ (DN50~DN1400).

Pressure range: 150lbs (PN10~PN20).

Available Operation: Gearbox, Electric, pneumatic actuator

Working temperature: -40℃~+120℃.

Marine butterfly valve is approved by DNV GL. It is with enough body thickness and strong resistance of pressure, The normal pressure is up to 2.0Mpa. With only a few parts, marine butterfly valves are easily maintenance and simple operation, only need to rotate 90 ° to quickly open and close, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics

widely used sea water, Ship-building